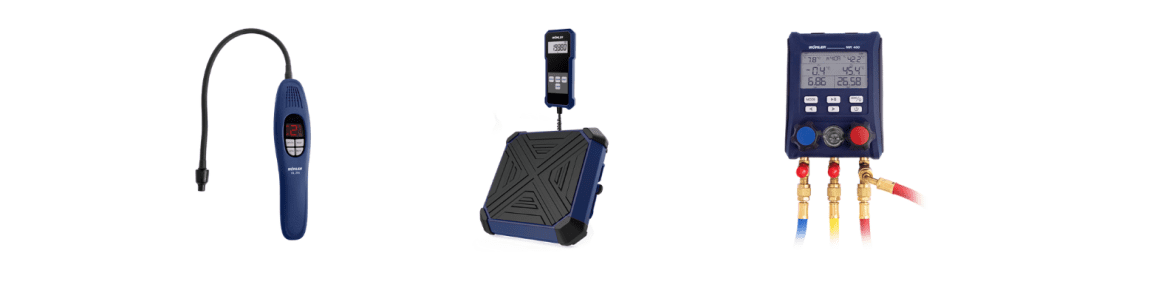

Take a look at the advanced tools from our German partner Wöhler, indispensable for checking cooling and heating systems (HVAC).

The modern environment requires and promotes energy efficiency and sustainable operations. Accordingly, the use of heat pumps is increasing worldwide.

With this growth comes challenges that require close monitoring, maintenance and professional intervention. Heating, refrigeration and air conditioning (SHK or HVAC) systems

must meet these challenges, and regular maintenance and performance checks are essential for effective operation.

In response to these needs, our German partner, a global manufacturer of innovative measuring, inspection and cleaning equipment Wöhler Technik GmbH has launched a new line of measuring equipment for the installation, maintenance and troubleshooting of heat pumps and cooling systems. With its new advanced tools, it enables refrigeration technicians to easily and robustly check the leak tightness and efficiency of heat pumps and refrigeration systems.

In accordance with the rules on F-gases (Regulation (EU) No. 517/2014) it is important that inspection and maintenance work involving interventions in the refrigeration circuit is carried out only by qualified technicians licensed for large refrigeration systems. However, certain activities, such as leak detection, which do not require intervention in the refrigeration circuit, are also accessible to other occupational groups, such as chimney sweeps and energy engineers. To this end, the refrigerant detector has become a key tool for fast and reliable leak detection.

Optimal tuning of heating and cooling systems is crucial for their economical operation. This is the only way to heat or cool to the desired temperature with low energy consumption. Your efforts are therefore making a very important contribution to energy efficiency. Another important point is the tightness of the system, as leaking refrigerants can pose a significant risk to the environment.

By choosing the right equipment and tools such as pressure gauges, thermometers, refrigerant quantity meters and leak detectors, refrigeration engineers can keep systems running efficiently while minimising the impact on the environment.

Wöhler offers a wide range of devices that are robust, easy to use and comply with industry standards, more below.

With new refrigerant detectors such as Wöhler RL 200 , you can quickly detect even the smallest amounts of refrigerant leakage and perform a leak test, which not only benefits the environment, but also you. With the ability to adjust sensitivity and the ability to automatically or manually zero the sensor, the meter provides accurate and reliable leak detection even in contaminated environments. The easy replacement of the sensor allows for a long lifetime of the detector, which contributes to the durability and reliability of the device.

občutljivost: 3 g/a senzor: ogrevana dioda- senzor plina življenjska doba senzorja pri normalni uporabi: ≥ 1 leto pogoji delovanja: delovna temperatura: 0 … 50 °C relativna vlažnost: < 80 % RV (brez kondenzacije) napajanje: 3 celice AA (alkalne)

In addition to refrigerant detectors, Wöhler also offers a number of other innovative solutions, such as MR 400 digital distributor for checking all key parameters of the refrigerant circuit. S RS 400 refrigerant weigher the technician can monitor any changes in the refrigerant quantity, allowing accurate monitoring of the filling and emptying of refrigeration systems.

TLAK merilno območje -1 … 55 bar točnost ±0.5 % celotne vrednosti skale TEMPERATURA merilno območje: -40 … 150 °C točnost: ±0.5 °C NAPAJANJE baterija: 3 AA baterije 1.5 V

ločljivost: 5 g točnost: ±0.5 % odčitka + 10 g napajanje: 5 AAA alkalnih baterij dimenzija: 271 x 271 x 74 mm življenjska doba baterije: 40 ur delovna temperatura: -10 … 40 °C vlažnost: 50 … 85 %

With versatile and easy-to-use solutions, Wöhler helps the SHK industry to meet the modern challenges of maintaining and operating heat pumps and cooling systems efficiently. Reliable measurement equipment sets new standards and enables professionals to achieve the highest standards of efficiency, safety and sustainability.

☏ Call us: +386 2 62 96 720

They are always available for opinions and explanations:

Subject matter expert: Barbara Čičak

Related articles:

Chimney sweeping equipment for a trouble-free heating season

New generation of leak detection

Mojca Kugler, source Wöhler Refrigeration – As cool as you are, October 2023

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]