Taking into account the correction of deviation is crucial for accurate temperature measurements of your meter

A digital thermometer is a meter that consists of a sensing (sensor) part and a digital display. Simpler thermometers They are “all in one” and the sensing part cannot be separated (replaced). Technological digital thermometers However, sensors often take the form of a temperature sensor with a connector. The latter allows you to change the sensor in case of failure or to use multiple sensors with one thermometer. In these cases we have to deal with two accuracies, one for the sensor and one for the thermometer. In practice, most users only follow the technical specification of the thermometer, which is no longer valid once the sensor has been replaced. This results in erroneous measurements and is not in line with established measurement procedures.

Digital thermometers are designed for higher accuracy measurements, and few people are satisfied with a tolerance of 1 °C or more. Therefore, the sensor must be calibrated with a thermometer – so part of the error needs to be corrected contributed by the replaced sensor. Whether or not this is possible depends on the thermometer manufacturer, but most technological thermometers allow it. It should be remembered that the thermometer was most likely calibrated with the original sensor when purchased, and the actual sensor error values themselves are never known to the actual user later on by the meter manufacturers, unless such a separate specification is requested at the time of ordering, e.g. as used by calibration laboratories.

The correction of the deviation shall be carried out by means of a calibration procedure and at the precise calibration points specified by the thermometer manufacturer (manufacturer’s protocol), to a correction of 0 (zero) or the minimum value according to the thermometer specification. This achieves the key objective of eliminating the bias, which is that the user does not need to take the correction into account in the normal use of the thermometer, as it is negligible. For everyday use it is very important and practical not to have to take into account the correction of the display for each measurement. This makes the work faster and more reliable in terms of measurement results. Although the correction of the deviation is carried out by calibration, this is not yet a calibration service in the classical sense. As the deviation correction is a matter of the manufacturer’s protocol and calibration points, it can be part of the preparation for user-required calibration if they are carried out in sequence.

The rectification service must be carried out by a reliable contractor, preferably an accredited laboratory before or after the first use or replacement of the sensor and/or before recalibration. Unprofessional implementation of the correction of a deviation often increases the error, which is why professional bodies and meter manufacturers alike often do not approve/enable user correction of the error. However, for those meters that do, great care is needed in the implementation of such fault correction, taking into account the contributions and risks involved.

In the case where several temperature sensors are used with one meter, we usually do not perform deviation correction with any of the sensors. Then both errors, the thermometer error and the sensor error (which must be known and added together), must be “manually” taken into account. If you were to correct for the bias with just one sensor and use other sensors, you would increase the measurement error of all the other sensors. This is something to pay close attention to.

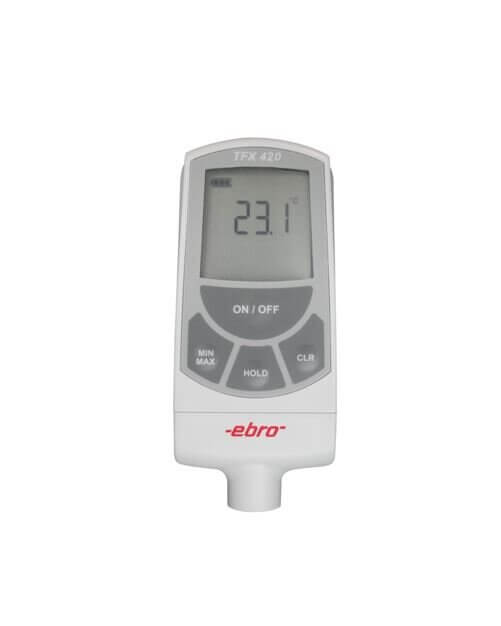

The ELPRO Calibration Laboratory and the ELPRO Authorised Service EBRO carry out deviation correction for the entire ELPRO range of portable temperature sensors in combination with ebro thermometers and other meters such as dataloggers, etc:

Author Barbara Čičak

March 2022

experts will offer you the best solution according to your wishes, requirements,

the scope or application!

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]