senzorji: vlažnosti: Rotronic HT-1 / temperatura: PT100 1/3 DIN razreda B obseg uporabe: -50 … 100 °C / 0 … 100 % RV točnost pri 23 °C: ±0.8 % RV / ±0.1 K

☏ Call us: +386 2 62 96 720

They are always available for opinions and explanations:

Aleksandra Lepenik, expert in temperature measurements

Measurement expert Zoran Lepenik

You are invited to read related articles:

By Blaž Tomaž Vertačnik, Aleksandra Lepenik; October 2023

Monitoring systems monitor and control data obtained from measurements of various physical quantities. They are used in industrial processes and anywhere else where measurements of specific physical parameters are needed to perform products or services. They simplify data transfer and, unlike monitoring data solely via memory units (data loggers), monitoring systems transfer all relevant data, which can be analysed in real time and used to generate accurate reports. With monitoring systems, your key measurement data is constantly at your fingertips, informing you in a timely and reliable manner if set (desired) values are exceeded inside or outside the workflow.

The monitoring system works with data loggers that store the data from the measuring instruments and automatically (wirelessly or via an interface) transfer it to a server or the cloud. The software analyses this data and stores it in a database. An alarm (audio or video) is triggered when the set threshold is exceeded. All relevant users are thus informed in real time via SMS, email or phone call. The data obtained can be accessed via all major platforms and is encrypted and carefully protected from unauthorised access. The data can be evaluated anytime and anywhere (close to the process itself, from home or elsewhere). The data display is fully customisable. External devices and existing systems can be integrated seamlessly, as can system extensions.

The advantages of monitoring systems include:

They perform three key functions: control, document/record and visualise measurement data – all fully automated.

Data can be retrieved anywhere, anytime via your smart mobile device in a format tailored to you.

Mobile app monitoring.

Connectivity and data storage in the cloud (CLOUD systems).

Very wide scope and applicability.

Saving time, labour and other costs.

Compliance with regulations such as GxP, FDA 21 – CFR Part 11, SOPs and others.

Monitoring systems can be used wherever the quality of a process requires the monitoring of certain physical parameters (temperature, humidity, pressure, gas analysis, etc.). This includes a very wide range of users such as: shops, warehouses, server rooms, HVAC applications, hospitals, laboratories, pharmaceuticals and many industrial activities.

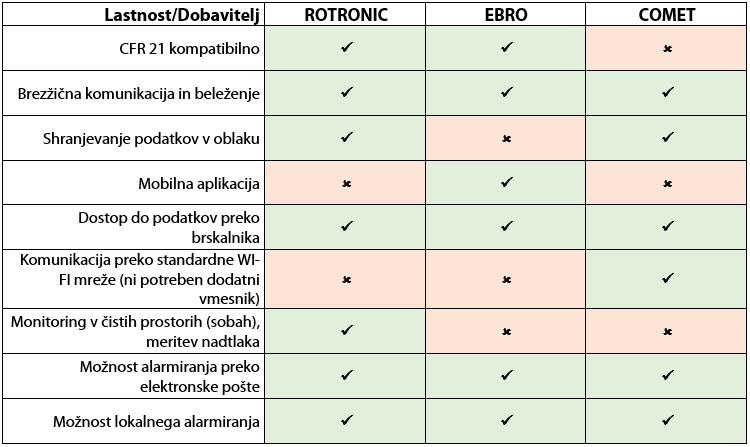

ELPRO LEPENIK offers you efficient monitoring systems from our partners Rotronic, EBRO and COMET from our technical programme. The three different systems can be combined, with the one that best suits the user as the base. A major advantage is the use of standard equipment, which can be upgraded at any time by the user. We add our customisation service to your application and system solution. The systems can also be maintained, either just monitored or additionally monitored, and if necessary, calibrated by the user at the time of purchase and on a periodic basis. The systems are available with IQ and OQ.

”Make the monitoring system work for you!”

Authors Katarina Žunko, Rok Samec

June 2022

Call us!

Tel: +386 2 62 96 720.

They are always available for opinions and explanations:

Read more: https: //www.elpro.si/kategorija-izdelka/elpro-storitve/

Moisture and temperature measurements are crucial in the food industry and food production

In order to develop the desired flavour, the cheese must be kept for several months at the appropriate temperature and relative humidity. Due to the high humidity required to ensure optimal air conditions, not every sensor is suitable for controlling ambient parameters. As the cheese factory must have high humidity and partial exposure to chemicals, it is important to calibrate the sensors regularly, including on site(ON SITE). The only way to ensure that the cheese ripening process and the associated quality of the product are flawless is to continuously measure the relative humidity and temperature during cheese production.

Temperature sensors are normally calibrated at 23 °C with a relative humidity of 10,35-80 % RH. This means that the sensor is most accurate at ±0.1 °C temperature and ±0.8% relative humidity. The further the temperature is from 23 °C, the greater the deviation can be.

Some cheeses emit ammonia during ripening. This can cause larger drifts in most humidity sensors.

For this reason, sensors need to be calibrated on a regular basis, which is made possible by our ELPRO Calibration Laboratory, where we calibrate your measuring equipment in accordance with the SIST EN ISO/IEC 17025:2017 standard.

ELPRO Adhesive offers you a range of high quality products for this application temperature sensors . We guarantee 24 h support, 100% output control, long product life and repeatability.

Environmental conditions in the food industry and food production are demanding. The quality of the cheese is therefore very dependent on the temperature and humidity values, which must be within precise parameters. If not, there is more waste. It is the climatic conditions of the dairy that rank producers in terms of quality and, consequently, in terms of higher yields.

The ripening of young cheese is the most important process in the ripening of cheese. It lasts for several days or weeks. The period is longer for sliced and hard cheeses, which can last from several months to several years. A good relative humidity and temperature gauge is essential to ensure the desired ripening of the cheese and the associated quality of the product .

Typically, the temperature in this process is between 7-15 °C and the humidity between 75-95 % RH. Even if the product had been stored in a humid cellar for the whole period, this would not have been sufficient. Constant control of humidity and room temperature is so important for the best ripening results.

ELPRO Lepenik , in cooperation with our partners, offers you the highest quality solutions for monitoring ambient conditions for effective results in the ripening process of the cheese: RMS-LOG data logger Rotronic , HF5 series of relative humidity and temperature transmitters Rotronic and DT722 relative humidity and temperature transmitter Michell .

As relative humidity and temperature monitoring is crucial in the food industry and HVAC applications, we offer relative humidity and temperature meters and other equipment from our partners here.

SEND US A REQUEST or CALL US. Our expert team will offer you the best solution for your needs, requirements and application.

At ELPRO Lepenik we are temperature and humidity experts for routine control and validation of various thermal processes.

Author Katarina Žunko

May 2021

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]