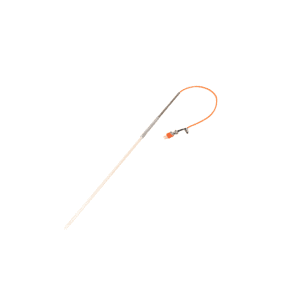

PRECISE temperature sensors

The temperature sensor product range includes a wide variety of highly accurate, calibration and reference temperature sensors for precision temperature measurements in laboratories, processes, industry, furnaces and other applications. Precise measurements are also known as accurate measurements or precision measurements. Precise measurements also involve knowledge of measurement, calibration and calibration.

“Digitalisation is sensor-driven, measurement-driven. No measurement, no data, no digitisation, Industry 4.0. And without data, there is no Industry 5.0, which will focus on people and the impact of data on the well-being of humanity and the planet.

Sustainability is based on a low-carbon society, minimising our impact on the environment. To measure environmental impact, we need sensors. To make accurate measurements, we need precision sensors. Of these, precision temperature sensors are the key to accurate temperature measurements, which have the biggest impact on emissions and energy efficiency. Temperature is a key factor in sustainability and energy efficiency. It all starts with the temperature sensor.

But the word precision strikes fear in users. Firstly, that it is expensive, and secondly, that they will see exactly what impact they are having on the environment and will be penalised for it with CO vouchers, tax burdens and higher costs. What they fail to realise is that it is old-fashioned metering, outdated automation, inadequate sensors, old installations, and poor and under-maintained maintenance that lead to costs – hidden costs that are huge, far greater than any other potential financial impact. Not to mention the impact on product quality and equipment lifetime.

There are currently five generations working in temperature measurement – from the older ones who still measure by eye – some of them with surprising accuracy – to users who have never even looked inside the furnace and believe only the information on the screen, on site or remotely. The former have a lot of experience, but this is no longer necessarily true because of new materials and additives that change the visual field, to the latter, who have no experience, are children of digitalisation and blindly believe the information on the screen, even if it is beyond all logical limits. In between are those with experience and modern knowledge, in different concentrations, so to speak. It all depends on the individual and their desire to train.

The first users of precision sensors were research laboratories, institutes, national standard holders and calibration laboratories. In the last decade, however, precision measurement, with all its positive impacts on sustainability and energy efficiency, has been rapidly moving into industrial measurement and processes, at critical control and regulation points. There is actually another extremely important area, which is product quality and maintaining the longevity of the stove. As already mentioned, the positive effects of precision temperature measurements for the user are so great that they are already difficult to measure, because they affect all current and future technological processes and financial situations. Those who have already realised this have been on a path of continuous improvement for years, with the strongest sectors being the aerospace and automotive industries, which are now also implementing good practices through directives to manufacturers. In this way, good practices and following the directives are spread down to the smallest manufacturer in the automotive and aeronautical industry. The key objective is to train users to recognise the benefits of precise and well-functioning equipment for measuring the temperature in furnaces.”

Aleksandra Lepenik, April 2022 from“Positioning the ELPRO Lepenik precision temperature sensor programme”