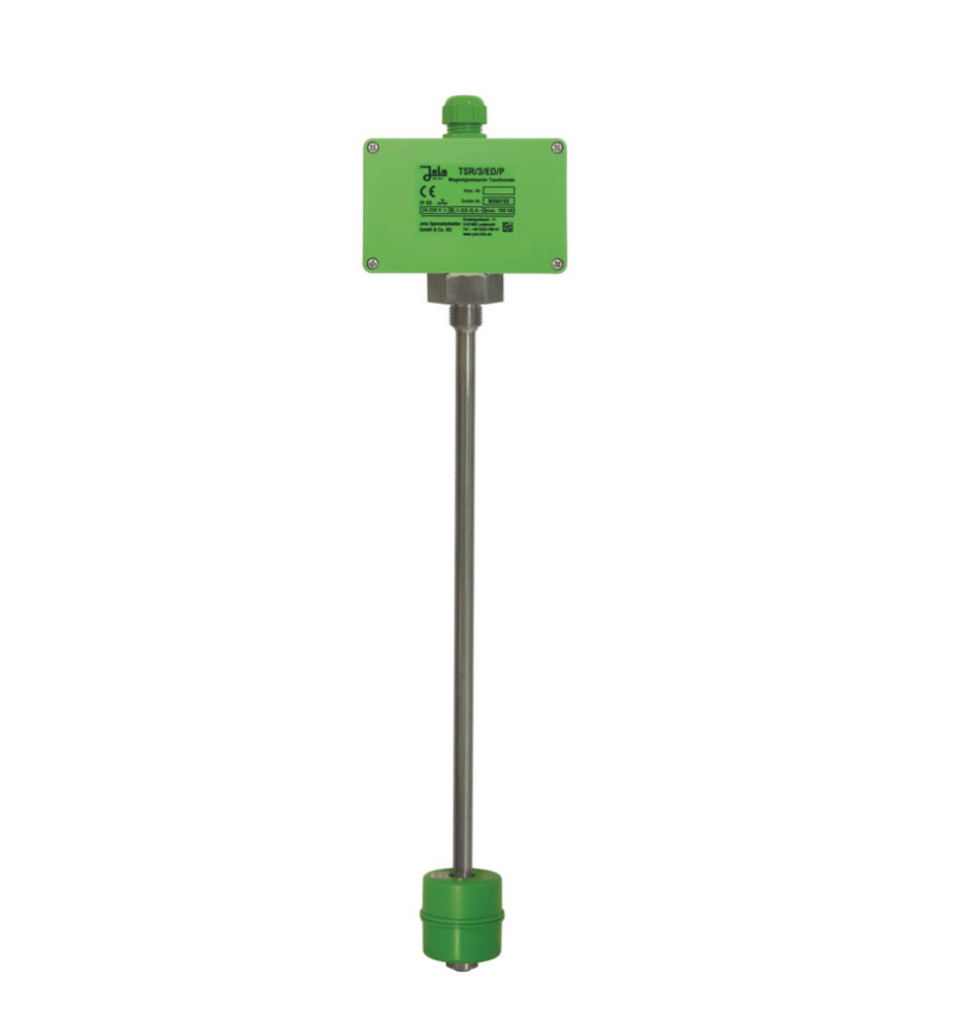

TSR/3/ED/P level dip switch with stainless steel rod JOLA

Po naročilu. Pošljite povpraševanje.

Delivery time: okvirno 2 tedna

- Switching voltage: between 24 V and 250 V AC/DC

- Switching current: between 100 mA and 2 A (0.4 A) AC

- Switching power: max. 100 VA

Description

The TSR/3/ED/P stainless steel JOLA level dip switch with rod is used for automatic level control, level indication, limit/point level detection, as an anti-drain protection or as an overfill protection for liquids in swimming pools. The level switch is designed for vertical installation. The tube is made of stainless steel, which prolongs its life.

Design and operating principle

TSR dip switches have a tube with reed contacts built in. The float is equipped with a permanent magnet. It moves freely up and down the pipe, activating the reed contacts as it ascends and descends. Note that the reed contacts are not locked, but switch only as long as the magnetic field is applied to them. When the float crosses an up or down contact, the contacts return to their original position. Reed contacts can also be restrained by the use of collars that restrict the movement of the float.

Features TSR/3/ED/P

- material of the level bar: stainless steel

- diameter of the level bar : 12 mm

- Length of level bar: optional up to 3,000 mm

- float: PP, 53 mm Ø x 50 mm

- for liquids with a density ≥ 0.8 g/cm³

- IP degree of protection: IP65

- junction box: PP, 120 x 80 x 55 mm

- mounting: vertical

- temperature range: -20 °C to +80 °C

- Compressive strength: max. 2 bar at +20 °C

- contacts NO, NC or OC max. 4

More technical information can be found under the Documentation tab in the attached pdf documents.

Examples of TSR/3/ED/P

Automatic tank emptying

- The float rises to the highest level with the fluid and triggers the NO contact, which sets the pump in motion via a sequential cycle. The fluid is pumped out. When the minimum level is reached, the NC contact at the bottom is activated, breaking the series circuit and ending the pump operation.

Automatic tank filling

- The float drops the liquid to the lowest level and triggers the NO contact, which sets the pump in motion via a sequential circuit. The fluid is then pumped inside. When the maximum level is reached, the upper NC contact is activated, breaking the sequential circuit and ending the pump operation.

Examples of standard use

with 1 float and 1 collar fitted over the upper contact

- It is advisable to fit an additional collar over the top contact. This allows the contacts to be switched after a circuit failure and avoids the rising fluid leaving the float outside the magnet’s area of influence on the contact. The length of the switch hose shall be such that when the float reaches the lower contact it rests on the retaining washer. The recommended distance between the bottom contact and the end of the switch corresponds to the minimum distance specified in the technical data of each TSR model.

with 2 or more floats and appropriate collars

- To ensure that you do not retain only the upper and lower contacts after switching on, several floats can be used together with appropriate collars. Please respect the minimum contact spacing for these applications.

Povpraševanje

You may also like…

For your victories, with our solutions. Call us:

Contact us.

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]