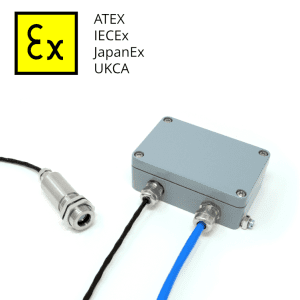

ExTemp infrared (IR) temperature sensor, ATEX and IECEx certified CALEX

Po naročilu. Pošljite povpraševanje.

Dobavni rok: 3 weeks

- IP 65 protection (NEMA 4)

- operating temperature range: -20 … +1000 °C

- 4 … 20 mA output, two-wire, looped

- cable lengths are 5 m, 10 m or 25 m as standard

- accuracy: ±1 °C or 1 %, whichever is greater

- repeatability: ±0.5 °C or 0.5 %, whichever is the greater

- response time t90: 240 ms

- spectral range: 8-14 μm

- dimensions: fi 20 x 150 mm

- Standards ATEX, IECEx, TIIS, CE, RoHS

Description

The ExTemp infrared (IR) temperature sensor CALEX with ATEX and IECEx certification is suitable for use in explosion hazardous zones 0,1 and 2 (gas) and zone 20 (dust). The temperature range of the infrared temperature sensor is -20 °C to 1000 °C. It is most commonly used in various industrial activities such as refining, paper production, automatic paint shops, oil wells and so on.

Benefits

- adjustable emission for all models: from 0.20 to 1.00

- measuring range: -20 … +1000 °C

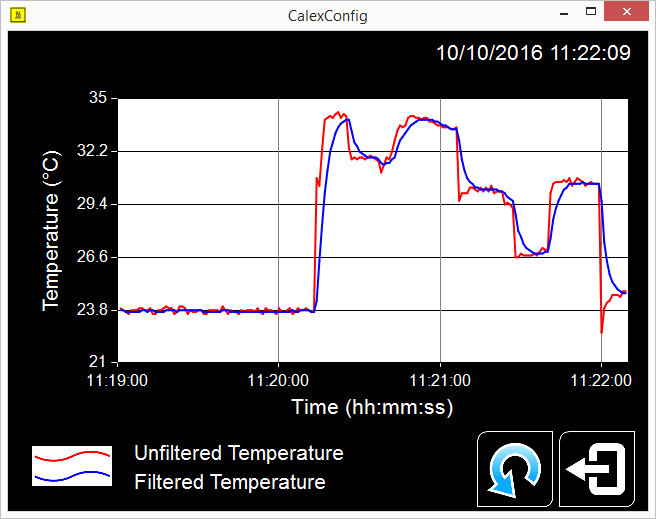

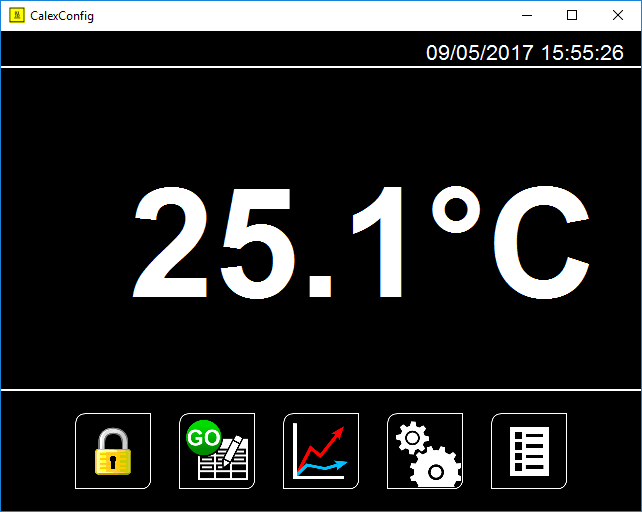

- fast response time and high stability

- IP 65 protection (NEMA 4)

ExTemp features

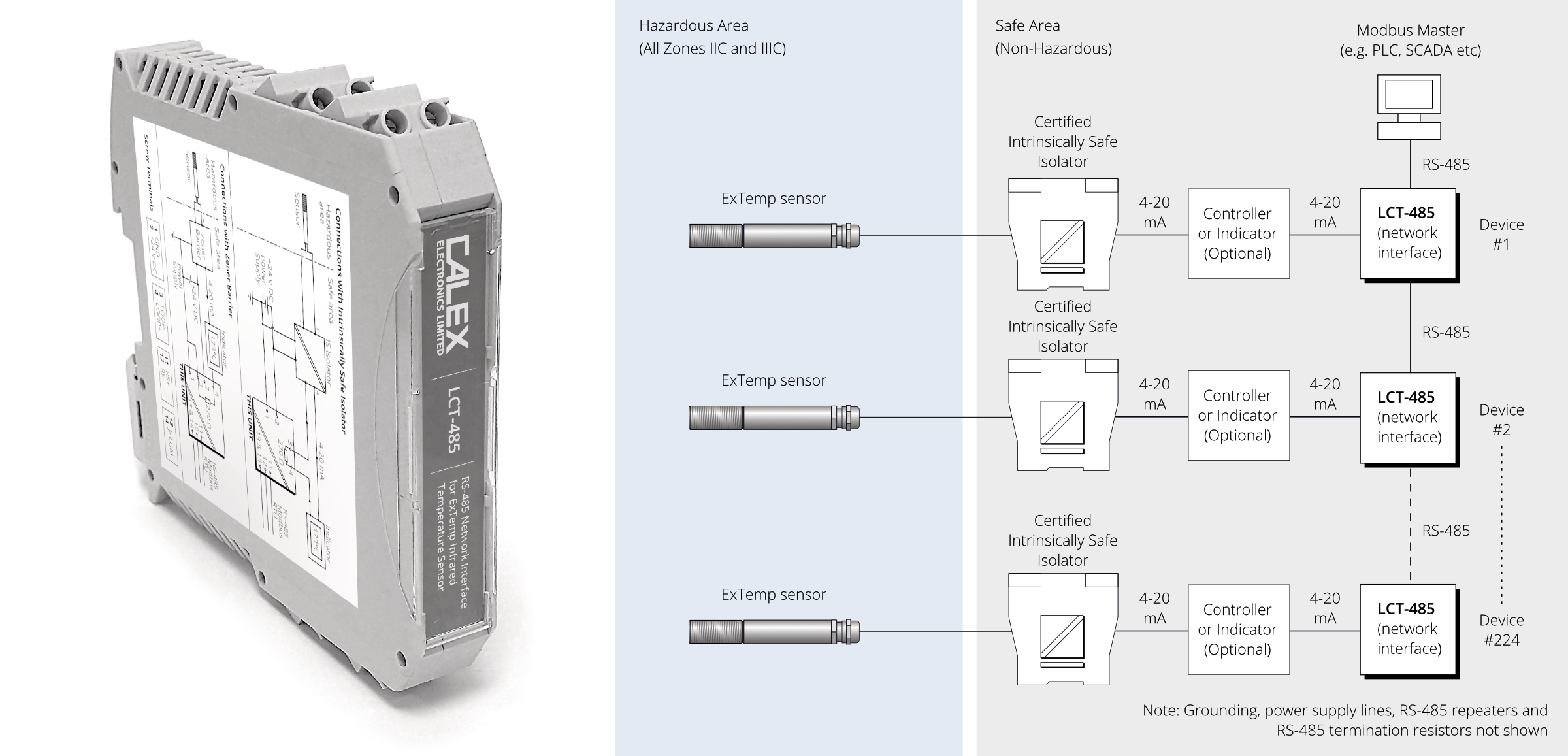

- optional RS-485 network interface and USB configuration tool

- not intended for measuring body temperature

- maximum temperature range 1000 °C

- minimum temperature range 100 °C

- accuracy: ±1 °C or 1 %, whichever is greater

- repeatability: ±0.5 °C or 0.5 %, whichever is the greater

- response time t90: 240 ms

- spectral range: 8-14 μm

- supply voltage: 12-24 V DC ±5 %

- material: stainless steel 316

- dimensions: fi 20 x 150 mm

- Weight: 475 g (with 5 m cable)

- Standards: ATEX, IECEx, TIIS (for use in Japan), CE, RoHS

Examples of use

Petrochemistry (monitoring)

The surface temperatures of bearings, gearboxes and motors in refineries and chemical plants can be monitored without contact, eliminating the need to replace contact probes that are easily damaged by vibration.

Petrochemistry (storage and processing of liquids)

The sensor can be installed in a Zone 0 environment, for example on top of a hazardous liquid tank or reactor, to measure the surface temperature of the liquid.

Paper industry

Dust in paper and packaging plants can cause fire and explosion hazards. ExTemp can be used to measure the temperature of paper fabric and monitor the condition of ATEX and IECEx classified hazardous areas.

Transport of coal

Its fast response time of 240 ms makes it ideal for measuring the surface temperature of coal and other bulk materials on conveyor belts where there is a risk of explosive dust.

Filling a gas cylinder

The surface temperature of explosive gas cylinders is monitored with ExTemp while they are being filled. Its Group IIC and T4 classification makes it suitable for almost all gases, including propane, butane, hydrogen and acetylene. The temperature of each cylinder is measured on the filling platform to help detect filling failures, calculate the final filled volume (in relation to pressure), ensure volume repeatability and improve filling speed.

Car painting

Solvents in car paints can cause gas explosions. The safe ExTemp can be used to monitor the temperature of containers, surface temperature of liquids, dust and the temperature of painted surfaces.

At sea

The 316 stainless steel housing and proprietary certification make it highly suitable for use on open platforms. In addition to measuring the temperature of the platform surfaces, it can also be used to measure the temperature of the sea surface.

For installation instructions, accessories and to order, please follow this link.

You can find much more useful information in the Documentation tab. Please refer to the technical documentation for options, add-ons and accessories.

Povpraševanje

You may also like…

For your victories, with our solutions. Call us:

Contact us.

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]