As we are very aware of the importance of the education of the younger generation for all of us, we have once again organised a professional excursion for the students of the FERI faculty at the ELPRO LEPENIK premises. They left us full of heads, knowledge and practical experience

At ELPRO LEPENIK, we know how important it is to work with educational institutions and students. Through practical examples and experience, we can help them understand the theory, influence their development and prepare them for their future careers. That is why it was an even greater pleasure to host Prof. Dr. Denis Đonlagić and his students of electrical engineering (FERI) in our company for the Automation course. Today’s Professional Excursion was designed to showcase the company’s operations and the education of students in a practical way. It consisted of five workshops presenting different aspects of work and work processes in our society.

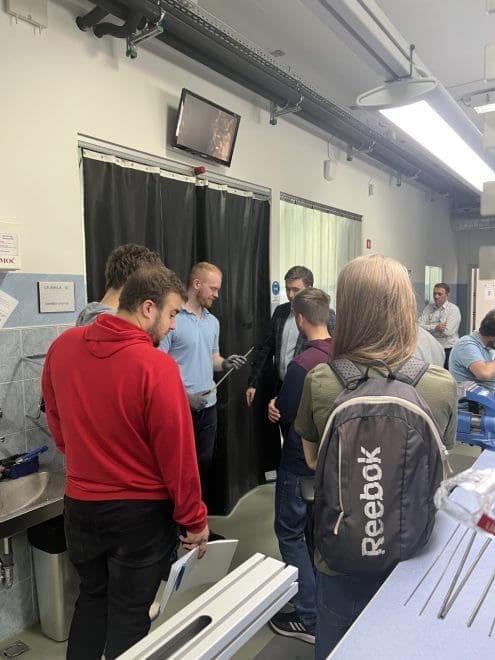

The first set of workshops focused on the production of temperature sensors. These workshops gave students an insight into the process of manufacturing sheathed temperature sensors by laser welding of the thermocouple; demonstration of different thermocouples with connector assembly and testing of the accuracy of the sensors in a liquid bath; demonstration of RTD RTD fabrication with Pt100 and Pt1000 sensors, bonding, connection materials, etc. Here, students learn about the wide variety of materials, machines, devices and accessories used in the manufacture of our products. They have learnt that manufacturing is not just about connecting and assembling components, but that a lot of attention is also paid to testing and quality assurance processes.

A workshop at our accredited calibration laboratory gave students a quick insight into calibration. A basic comparative calibration of the temperature in the liquid bath was carried out on the basis of a concrete example. They learn about the standard, correction, error and uncertainty. They also learnt about the traceability process and tried their hand at measuring surface temperature.

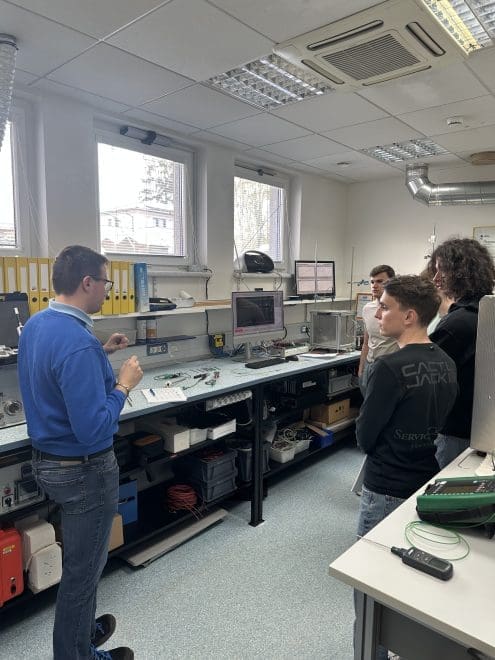

The last workshop was dedicated to the presentation of the work of the Service and Technical Support Department. The content of this workshop introduced the students to the wide range of instrumentation/control technology/equipment from our partners. They looked at three types of on-line monitoring: monitoring of temperature and pressure in our boiler room – fixed installation; on-site monitoring of temperature and relative humidity with data transfer via Ethernet to the cloud; on-site monitoring of temperature and relative humidity with data transfer via IoT communication. They learnt about the advantages and disadvantages of each of these control models and the purpose of digitising, automating and optimising processes.

ELPROVČKI hope that the students of electrical engineering took away as much useful knowledge and experience as possible from today’s excursion, which will certainly come in handy in their further education and career development. We were very happy to hear their questions and their enthusiasm, which means a lot to us.

Our company also offers students of electrical engineering the opportunity to carry out compulsory practical work throughout the year, as well as an open job opportunity with the company after the internship.

☏ Call us: +386 2 62 96 720

They are always available for opinions and explanations:

Aleksandra Lepenik, expert in temperature measurements

Measurement expert Zoran Lepenik

Mojca Kugler and Aleksandra Lepenik, May 2023

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]