Transport I.S. Process Moisture Analyser Michell

Po naročilu. Pošljite povpraševanje.

Delivery time: Approximately 4- 6 weeks

- Sensor technology: ceramic metal-oxide humidity sensor from Michell

- measuring range: -100 … +20 °Cdp

- calibration range: -100 … +20 °Cdp

- dew point accuracy: ±1 °C between -60 and +20 °Cdp

- accuracy of moisture content: ±10 % of reading

- dew point accuracy: ±2 °C between -60.1 and -100 °Cdp

Description

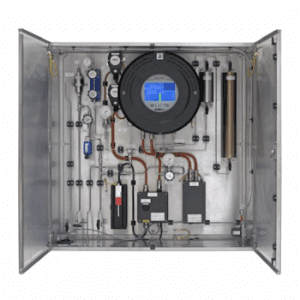

The Michell Process Moisture Analyser is a heavy duty industrial hygrometer system for measuring moisture in high pressure, process gases and vaporised liquids. It is used in natural gas processing applications, petrochemical plants and industrial gas production plants.

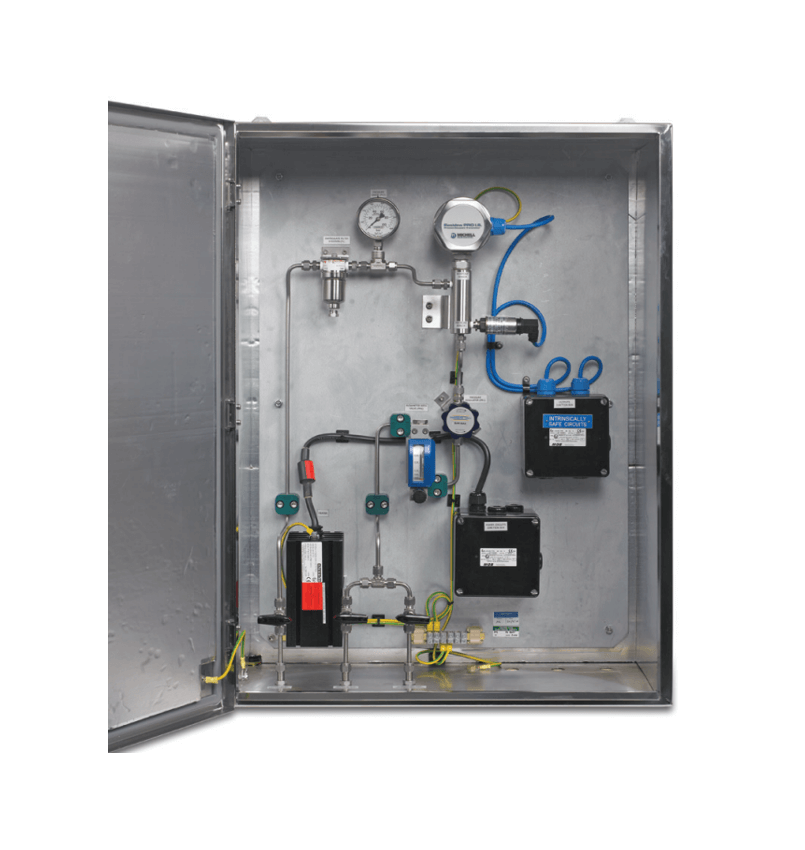

The Michell Transport I.S. Process Moisture Analyser combines Michell’s proven ceramic metal oxide moisture sensor with a sample conditioning system to achieve reliable and easy-to-use performance for flammable and non-flammable gases.

Traffic I.S. is available in single or multi-channel configurations. Up to four Promet I.S. or Liquidew I.S. moisture and liquid analysers can be combined via a multi-channel control unit.

Features Transport I.S.

- Sensor version: Easidew PRO I.S.

- simple, cost-effective operation and low maintenance

- immunity to chemical attack by H2S (hydrogen sulphide), mercaptans and other sulphides

- protection against glycol and other liquid contaminants

- accurate direct dew point measurement at process pressures up to 45 MPa

- the range of humidity from ambient to ppb level with a comprehensive list of hygrometric units, including key natural gas parameters

- outputs: two adjustable 4-20 mA outputs

- communication: digital communication based on Modbus RTU

- calibration: calibration integrity ensured, traceable to British (NPL) and American (NIST) national humidity standards

- user-configurable or ”real-time” active pressure compensation for moisture content calculation

- multi-channel with up to 4 independent measurement channels

- ES70 sample user-configurable systems

- Power supply: 85-265 V AC or 10-72 V DC

- housing protection: stainless steel, IP66

- Certifications for use in hazardous areas: ATEX, IECEx, TC TR, FM, CSA

Areas of use, applications

- production and processing of natural gas

- drying of pipelines

- offshore pipelines

- monitoring the transmission pipeline

- fiscal gas metering

- quality of gas storage

- hydrogen production, storage and transport, including natural gas injection

- LNG (liquefied petroleum gas) processing and receiving terminals

Articles

You are welcome to view the articles:

”Measuring cleanliness in hydrogen production”

,

”Monitoring impurities in Syngas”,

Measurement of moisture in LNG production.

Povpraševanje

You may also like…

For your victories, with our solutions. Call us:

Contact us.

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]