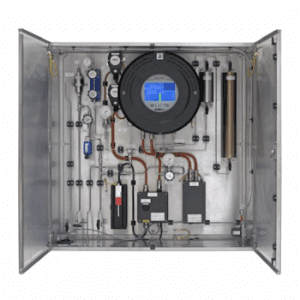

QMA601 Michell Process Moisture Analyser

Po naročilu. Pošljite povpraševanje.

Delivery time: Approximately 4- 6 weeks

- fast and reliable measurement in the measuring range: 0,1 … 2000 ppmV

- Accuracy: ±0,1 ppmV at <1 ppmV and 10 % of reading between 1 … 2000 ppmV

- built-in process gas check

- IECEx, ATEX, UKCA, TR CU Ex certified for Exd fire resistance, cQPSus certified for explosion resistance

- 14 internal alarms

- 21 predefined carrier gases and 3 user-defined gases

Description

The QMA601 Process Moisture Analyser provides highly reliable, fast and accurate measurement of moisture content in a wide range of carrier gases. It has a lower detection limit of 0.1 ppmV with reliable accuracy (sub ppm) when measuring trace moisture levels. Michell’s latest development of Quartz Crystal Microbalance technology enables the process analyser to efficiently measure moisture levels, even in gases with changing composition. QMA601 is fully certified for use in hazardous areas.

The QMA601 Process Moisture Analyser requires minimal routine maintenance, providing cost savings. It features an intuitive, easy-to-use “through-the-glass” touchscreen interface. It also allows the analyser to be interrogated and configured without the need for a hot work permit.

The QMA601 is suitable for use in natural gas applications containing up to 20% hydrogen without the need for additional modifications.

Features of QMA601

- measurement technology: fast-response Quartz Crystal Microbalance

- calibration range: 0,1 … 700 ppmV (only valid for the standard version of the 30-30 s cycle)

- measuring range 0,1 … 2000 ppmV

- accuracy:

- ±10 % of reading between 1 … 2000 ppmV

- ±0,1 ppmV between 0,1 … 1 ppmV

- Reproducibility:

- ±5 % of reading between 1 … 2000 ppmV

- ±0,1 ppmV between 0,1 … 1 ppmV

- detection limit: 0,1 ppmV

- units available: ppmv, ppmw, mg/Nm3, vapour pressure (Pa), dew point (°C/°F), lb/MMscf

- response time:

- T63 <2 min to step forward in any direction

- T95 <5 min to step forward in any direction

- Automatic calibration: internal humidity generator, calibrated, traceable to NPL & NIST

- sensitivity: 0,01 ppmv or 1 % of the reading, whichever is greater

- Power supply: 85 … 264 V AC, 47/63Hz or 24 V DC (ATEX/UKCA/IECEx), 24 V DC only (cQPSus)

- Alarms: 1 x system alarm, no voltage switch 3 x process alarms, selectable for different parameters, no voltage switch

- analogue signals: 2 x 4 … 20 mA or 1 … 5 V (optional)

- maximum load resistance: 500 Ω for 4…20 mA and minimum load 1M Ω for 1…5 V

- Digital communications: RS485 Modbus RTU, Modbus TCP

- data logging: available on the analyser (limited number of values) or via software applications

- Local interface: 7″ colour LCD with intuitive HMI

- Electrical connections: M20 cable entry ports

- Inlet pressure: 2 barg

- outlet pressure: 1 barg

- gas flow: 300 ml/min total flow

- Sample gas temperature: 0 … +100 °C

- the working environment:

- the analyser itself: +5 … +45 °C up to 90 % RH

- of the analyser in the sampling system: -20 … +55 °C up to 95 % RH (equipped with heater/thermostat and/or cooling of the housing as appropriate to maintain +5 … +45 °C internal temperature)

- mechanical characteristics

- cover and housing body: copper-free LM25 aluminium (EN AC-42000), less than 0,6 magnesium

- Glass window: heat-resistant, explosion-proof, polyester-coated, IP66, NEMA 4

- Gas connections: 1/8″ NPT(F)

- Weight: 35 kg without sampling system

- housing of the sample system: 316L stainless steel

- hazardous area certificates:

- ATEX/UKCA II 2 GD Ex db IIB+H2 T6 Gb, Tamb -40 °C…+60 °C,

- IECEx Ex db IIB+H2 T6 Gb, Tamb -40 °C…+60 °C

- cQPSus CLS I, Div 1, Group BCD T6, Tamb -25 °C…+55 °C, CLS I, ZONE 1, AEx db IIB + H2 T6 Gb, Ex db IIB + H2 T6 Gb, Tamb -20 °C. ..+55ºC

- TR CU 1Ex d IIB+H2 T4 Gb X, 1Ex tb IIIC 130 °C Db X and 1Ex d IIB+H2 T3 Gb X, 1Ex tb IIIC 195 °C Db X

- maintenance-free 3 years

Areas of application

- dehydration of natural gas using a molecular sieve

- natural gas transmission and storage

- Refinery catalytic reforming – monitoring recycled gas

- ethylene and propylene production

- LNG production/liquefaction

- glycol dehydration of natural gas

Special features

Michell Instruments delivers proven quality with 40 years of moisture measurement expertise built into the instrument design.

Other designations: QMA 601, QMA_601, QMA-601

Povpraševanje

You may also like…

For your victories, with our solutions. Call us:

Contact us.

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]