DP 700 Leak Tester Wöhler, basic set

Po naročilu. Pošljite povpraševanje.

Delivery time: approximately 2-3 weeks

- pressure

- Principle: piezoresistive solid-state sensor

- measuring range: ±7,000 Pa

- volume flow

- Principle: anemometer z hot hot foil

- measuring range: 0.0000 to 55.00 L/s

Description

The Wöhler DP 700 basic leak tester set enables the detection of leaks in air ducts.

Depending on the time of the tests, the Wöhler DP 700 can detect leaks in air ducts, components and installations during production or before taking over the plant. So try Tightness z device Wöhler DP 700 important Contributors k providing quality between production and installation and Consequently k Energy efficiency Climate and ventilation systems.

The energy efficiency of VAC systems is increasingly demanding. Channel tightness plays a particularly important role. This aspect represents the greatest potential for energy savings, if the air flow can be adapted to the actual needs in conjunction with a low leakage rate. S of this from the point of view of or to be v future many more See Low Leakages From devices and channels. This will make proper measurements even more important.

Main features

- leakage tests in large air leakage zones: from individual components to complete systems, which comprising Read more 100 m²

- Leakage tests on air-conditioning systems, in switch cabinets, climate test cabinets, heat exchangers, lockers For technology clean cleanroom technology and Other enclosures

- testing leakage v premises

- on-site and laboratory measurements on structural elements(e.g. OSB, windows)

- can be included in the final batch production inspection routine, including optional remote programme management (controlled from a PC via USB)

- Suitable for lower capacity tests(40 l/s), 110 V, 60 Hz

Leakage tests on over 100 m2 of installed duct systems.

Component testing on small, individual components.

Wöhler DC Series software for data transfer and further processing(optional documentation kit ).

Quality control during batch production of ducts and components.

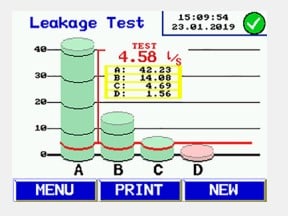

A graphical display of the results, which can be printed.

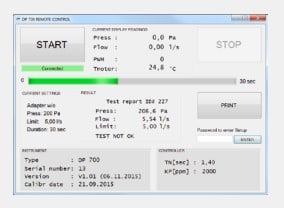

Control of the Wöhler DP 700 via USB with optional remote program control(e.g. for inclusion in the final inspection routine in batch production).

Basic set DP 700 – 7135

- Wöhler DP 700 leak tester

- air hose 3.75 m

- 4 m air hose

- pressure hose 10 m

- calibration report

- 2.5 m power cable

- adapter 0.3; 2 brass plugs

- connector for negative pressure hose

- filter

- silicone grease

- 2 transport cases

Documentation set – 7130

- Wöhler TD 100 high-speed thermal printer

- 10 rolls of thermal paper

- Wöhler DC Series computer software

- USB cable

Sealing set for round air ducts – 7103

- K-pump with various adaptors

- 5 sealing bladders for round systems size 3 – for nominal size 100 – 250 mm

- 5 sealing bladders for size 5 round systems – for nominal size 200 – 400 mm

- 5 sealing bladders for size 10 round systems – for nominal sizes 315 – 630 mm

- 15 hose clamps suitable for pipes Ø = 3,2 – 11 mm

Use

- leakagetests in large air leakage zones: from individual components to complete systems, which comprising Read more 100 m²

- Leakage tests on air-conditioning systems, in switch cabinets, climate test cabinets, heat exchangers, lockers For technology clean cleanroom technology and Other enclosures

- testing leakage v premises

- on-site and laboratory measurements on structural elements(e.g. OSB, windows)

- can be included in the final batch production inspection routine, including optional software remote control (controlled from a PC via USB)

- Suitable for lower capacity tests(40 l/s), 110 V, 60 Hz

Functionality

- Preskus leaks from DIN EN 12599 – for to be handed over air conditioning and ventilation systems

- test leakage v according to s standard DIN EN 14134 – check installation of residential ventilation of ventilation systems

mErasing class Leakages v stock s standards DIN EN 13779 for systems ventilation channels and component v stock s Standards DIN EN 1507, DIN EN 12237, DIN EN 13403 and DIN EN 3180.

- meets high precision requirements, specified in DIN EN 1751 and DIN EN 15727 for measurements on individual components (±0.0009 l/s)

- includes adapter for measuring range < 0.3 l/s

- easy management z management of the operator or professional method

- automatically or manually measuring sequence

- Option separate measurement differential pressure

- measuring values v desired units without manual conversion

- print out the on-site measurement reports using a thermal printer(optional accessory)

- practical set in 2 cases, easy to transport and store

Data management

- store up to 100 measurements

- data permanently stored in the instrument

- Customer and data management with Wöhler DC Series PC software (optional)

- data transfers via USB

- print the measurement results, including the graphic diagram, on a printer (optional)

- Upgrade to the“ROUND AIR CONDUCTOR SET” (7103)

Other designations: DP700, DP-700, DP_700

Povpraševanje

You may also like…

For your victories, with our solutions. Call us:

Contact us.

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]