Individual health and a clean environment are two of society’s top goals, and individual responsibility in food selection and its environmental impact is critical. It is important to raise awareness about this since it affects future generations and the environment as a whole.

Home composting and the use of humus as a natural fertilizer for the garden are becoming increasingly popular. This is critical for minimizing biological waste, which accounts for more than a quarter of household waste. Furthermore, composting and utilizing humus offers numerous environmental and food production benefits. It contributes to improving soil quality, enhancing crops, and giving a better diet while also being a purely ecological or biological technique of fertilization.

Temperature control is critical in the formation and processing of compost. In relation to this, we propose temperature sensors for compost temperature monitoring below.

It is critical to control the temperature of the compost when composting organic waste. This is determined by a variety of elements, including moisture, air, and microbes that degrade organic matter in the compost. The temperature can exceed 70 °C in this instance.

However, too high a temperature might harm the decomposition process and, as a result, the quality of the finished product by killing beneficial bacteria. Furthermore, too high a temperature might cause the compost to dry up or even catch fire.

As a result, it is critical that the temperature in the compost be managed and kept at an optimal level to allow for the efficient breakdown of organic elements in the compost and the development of a high-quality and usable final product. Special temperature sensors are employed to control the temperature in the compost, allowing accurate monitoring of the temperature in different regions of the compost.

As previously stated, proper temperature management in the compost is critical for the effective manufacture of excellent compost. Competitive temperature sensors frequently fail owing to poor design and manufacturing, which can result in inaccurate measurements and unreliable data.

As a result, at ELPRO Lepenik & Co., we have created a dependable and cost-effective solution for temperature control in compost, based on precisely produced temperature sensors and modern data collecting and processing technology. Our technology allows accurate temperature control in the compost, ensuring optimal conditions for the decomposition of organic substances and the generation of high-quality and usable compost.

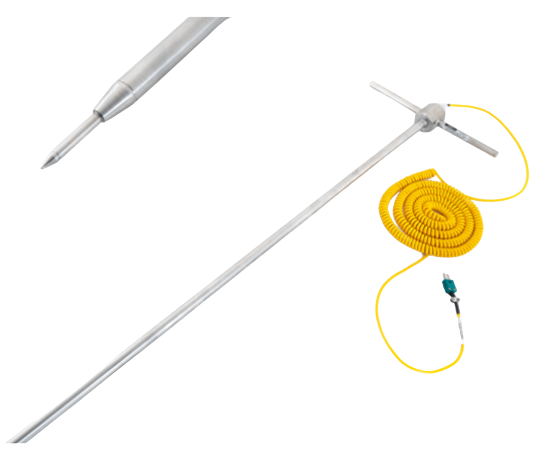

ELPRO Lepenik & Co. provides industrial penetration temperature sensors ideal for temperature readings in compost, humus, and silage materials. It is a type of temperature sensor that can be changed to the necessary length and has one or more temperature measuring levels. Sensors typically have one level of temperature measurement at the tip of the sensor.

They are built of exceptionally strong and resilient stainless steel, allowing the user to push them through layers of compost, humus, or other ensiled materials using the T-handle. The mistake rate is kept to a minimum thanks to its sturdy architecture.

The 2230 4430 penetration temperature sensor is made on the basis of a thermocouple and is connected to industrial thermometers, e.g. TFN 520 – the most commonly used version.

The 2240 3740 penetration temperature sensor is made on the basis of a resistance sensor and is connected to precision thermometers, e.g. TFX 430 or TFX 420.

The main difference between the two variants of temperature sensors is whether they take quick and frequent observations (2230 4430) or rarer and more precise measurements (2240 3740). Temperatures between -50 and 100 °C are common during operation, but the designs allow for considerably higher temperatures, so we do not establish temperature limitations. The most frequent sensor lengths are 1000 mm, while intermediate lengths ranging from 1000 to 6000 mm are also possible.

We tailor both models to the needs of the customer, from the length and shape of the handles to the connectors and gauges (thermometer, datalogger, display …). Adjustment does not imply paying additional money. These designs are always manufactured to order and can be fully personalized, even in different pricing ranges. The most significant aspect is the end result, dependability, and extended service life.

The new generation 2280 4650 hummus thermometer is introduced as a cutting-edge instrument for measuring humus temperature. This advanced custom-design temperature sensor has a variety of exceptional features that enable accurate and dependable temperature monitoring in this crucial environmental element.

The built-in temperature display of these thermometers allows for a rapid examination of the data at the place of measurement. This functionality means that users may directly monitor temperature fluctuations in the humus and instantly alter the necessary measures.

Furthermore, they have a durable design that allows them to perform for an extended period of time in the severe conditions of the humus environment. They are resistant not only to moisture and dust but also to potential shocks and vibrations, ensuring dependability and long service life.

Another of its distinguishing characteristics is its rapid responsiveness. Whether the temperature is changing quickly or slowly, the 2280 4650 thermometers will deliver a quick and accurate reading. This capability is instrumental in the research, where it is critical to collect data in real-time.

In addition, the 2280 4650 thermometers include temperature data logging using NFC technology. This feature enables data to be easily transmitted to suitable devices such as smartphones, allowing for further analysis and tracking of long-term humus temperature patterns.

ADDED VALUE: Industry temperature sensors have a 5-year manufacturer’s warranty and are made in Slovenia.

All temperature sensors and thermometers can be custom-made to your specifications. The most popular varieties are displayed on the internet; nevertheless, production is primarily created to order.

We at ELPRO Lepenik are temperature and humidity experts for routine checks and validations of diverse thermal processes.

In the ELPRO Calibration Laboratory, we calibrate the temperature sensors after manufacture and deliver them with an accredited calibration certificate (SIST EN ISO/IEC 17025).

☏ Call us: +386 2 62 96 720

For opinions and explanations, they are always available:

temperature measurement expert: Aleksandra Lepenik

measurement expert: Zoran Lepenik

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]