senzorji: vlažnosti: Rotronic HT-1 / temperatura: PT100 1/3 DIN razreda B obseg uporabe: -50 … 100 °C / 0 … 100 % RV točnost pri 23 °C: ±0.8 % RV / ±0.1 K

☏ Call us: +386 2 62 96 720

They are always available for opinions and explanations:

Aleksandra Lepenik, expert in temperature measurements

Measurement expert Zoran Lepenik

You are invited to read related articles:

By Blaž Tomaž Vertačnik, Aleksandra Lepenik; October 2023

At the ELPRO Calibration Laboratory, we accredited calibrate your measuring equipment in accordance with CQI standard guidelines.

The CQI (Continuous Quality Improvement) range of standards is issued by the North American Automobile Association AIAG.

The fourth edition of the CQI-9 (Special Process Heat Treat System Assessment and Calibration) guidelines was published in 2020 .

As a result, new requirements for automotive and aerospace customers are placing demands on calibration service providers. These include meeting the requirements for certified calibration. Chapter 1.3 of the Guideline specifically addresses the requirements for calibration laboratories to comply with ISO 17025.

The Instruction further refers to calibrations of thermocouples and the requirement for traceability of calibrations. All thermocouples must be calibrated before use in the range in which they will be used, etc.

In this industry, extreme care is therefore needed when selecting and considering a calibration provider, as the provider must be accredited to SIST EN ISO 17025. In the case of an inadequate calibration provider (or one that does not fully comply with the requirements of CQI-9), the assessment or audit may order the shutdown of the customer’s production process.

The CQI-9 guidelines are dictated by the requirements of the AMS 2750 standard (aerospace and automotive).

The ELPRO Calibration Laboratory will provide you with an accredited temperature calibration in accordance with CQI-9 guidelines.

The third edition of the CQI-11 Guidelines was issued in October 2019. CQI-11 was developed to help better evaluate the quality systems available in processes where electroplating is present (automotive OEM coatings). The galvanic coating must be assessed at least once a year.

Previous revisions of the CQI-11 guidelines did not provide sufficient detail to guide the user to acceptable test methods and results (accredited calibration). This edition provides the necessary level of detail and is aligned with CQI-9. It refers to applications related to pyrometry (IR radiation for remote determination of the temperature of objects, in the case of very high temperatures).

These guidelines are a supplement to the IATF and apply to all automotive suppliers worldwide. The requirements of this issue also apply to the aviation industry.

At ELPRO Lepenik, we manufacture a reference thermometer with a temperature sensor length of 1m, a immersion depth of 950 mm, a diameter of 4 mm and a special PTFE protective coating in accordance with CQI-11. The reference measuring set is supplied with an accredited calibration certificate (note: the chosen dimension corresponds to the standard, but can be customized).

ELPRO Calibration Laboratory can calibrate your thermometers and temperature sensors in accordance with CQI-11 guidelines and perform accredited calibration of the thermometers you use for bath temperature control.

Author.

August 2021

Call us!

Tel: +386 2 62 96 720.

They are always available for opinions and explanations:

Read more: https://www.elpro.si/elpro-laboratorij-za-kalibracije/

ROTRONIC relative humidity and temperature meter - for the paper industry

From our partner ROTRONIC we present HP-GTS – the solution for the paper and printing industry, for the precise measurement of humidity and temperature, and the related equilibrium relative humidity in the paper and printing industry.

Discussions on environmental impacts during paper storage, transport, printing and finishing have existed since the beginning of industrial paper production. Generations of professionals have had to cope with major negative impacts in order to monitor and control temperature and humidity. Despite years of testing, some relationships are still not sufficiently clarified, if at all. There is still a lot of controversy in the practice of paper converting, in particular about the relationship between the atmosphere, paper and printing. In modern production facilities, paper intended for offset printing is prepared at a relative humidity of 50 % ± 5 % and at 40 % ± 5 % for digital printing. These humidity characteristics must be continuously monitored at all stages of the production process.

To keep the paper in optimal condition for the printing process, it is wrapped in a special packaging material that protects it from environmental influences and changes. The paper manufacturer has minimal influence on how the paper bundles or fibre gaps will react to the environmental conditions in the premises of the printers, bookbinders or end-customers.

Under normal printing conditions, there are problems related to direct atmospheric conditions. When printing problems occur, such as duplication of dots, incorrect entries, overlapping, curling, edge bleed, wrong dimensions, these atmospheric effects become significant. This is more likely to happen in seasons with extreme weather conditions – hot summers and cold winters. The latter causes poor print quality, especially in the levelling process. This has a negative impact on production processes, such as incorrect entries or interruptions due to breaks.

The value describing the evolution of relative humidity as a function of temperature depends on the accuracy of the measurements made. Here, the temperature measurement must be very precise. This means using thermometers that read in tenths of degrees.

Although accurate temperature measurements are relatively simple, the same cannot be said for reliable measurements of absolute or relative humidity. The practical problem with all humidity measurements is that they are made on relatively small amounts of moisture.

At a temperature of about 20 °C, an increase in moisture content of about 2 g/m³ causes an increase in relative humidity of about 10%.

As a hygroscopic material, paper strives to achieve equilibrium with the humidity of its surroundings. For this reason, the humidity of the air inside the paper structure must be equal to the humidity of the paper bundle. This value indicates the degree of equilibrium between the relative humidity of the paper and the ambient air. The equilibrium relative humidity ( ERH ) can be defined as the value of the relative humidity of the atmosphere at a given temperature at which the paper will neither gain nor lose moisture. If there is a difference between the relative humidity (% RH) of the atmosphere where the paper is located and the ERH of the paper, water vapour exchange can occur. This results in a change in the ERH and moisture content of the paper, which affects the quality of the paper. If the % RV and ERH are equal, no exchange will occur and all parameters will remain stable. In this respect, ERH is a very important factor in ensuring paper capacity and quality.

To determine the relative humidity of the air or the equilibrium relative humidity of the paper, it is necessary to measure the change in a measurable humidity-dependent parameter. Such parameters affected by moisture fluctuations include, for example, changes in the length of paper fibres, the conductivity of electrolytes and changes in the resistivity of semiconductors. In the practice of paper production and converting, these methods are widely used in measurement and control systems. The methods used to calibrate humidity instruments are very accurate and are based on the principle of measuring the dew point and determining psychrometric differences.

By measuring the relative humidity and the atmospheric temperature, it is possible to determine whether the quality of the paper will change after unpacking, thereby adversely affecting the planned printing. A difference between ERH and external humidity of up to ± 5 % RH is acceptable. When the humidity difference is too large (> 8-10% RH), water vapour is exchanged too quickly, resulting in deformation of the paper edges. The latter leads to poorer print quality and affects the amount of paper wasted.

Paper moisture content of more than 60% ERH can extend the drying time of the ink up to three times longer than usual. The optimum atmospheric humidity for the storage and transport of paper or cardboard is approximately 45 % RH (for temperatures between 10 °C and 30 °C). By observing the above storage conditions, ink drying can be optimised when the paper bundle is collected (to avoid major temperature changes in humidity). The length of time bundles of paper or cardboard can be stored depends on the temperature difference between the bundle and the ambient conditions, and the size of the bundle. As a general rule, the storage time is between one and two days, with a difference of 10 °C and a volume of 1m3. If the paper humidity is too low (<42% RH), it can lead to static, which affects the performance of the printing machine. This takes multiple sheets at once, leading to maintenance costs and delays.

Unwanted paper changes and printing delays can be avoided by measuring the ERH of the bundles and the temperature, using a relative humidity and temperature meter. From the Rotronic range, we offer the Hygropalm HP-GTS kit with portable instruments for measuring equilibrium relative humidity and temperature (paper bundles) with state-of-the-art technology.

HP-GTS replaces the long-standing GTS and GTS-set products.

Next to the meter Hygropalm HP-GTS we offer a number of sensors of different models and other instruments:

– Sword-shaped sensors for measurements in paper bundles

– sensors for measuring relative humidity and temperature with high accuracy

– sensors for measuring humidity, temperature and dew point

– mini relative humidity and temperature sensors

– calibration devices for relative humidity sensors

KEY FUNCTIONS:

Benefits:

Areas of use, applications:

measuring humidity in bundles of paper, cardboard and textiles for paper and textile machinery and printers.

A major improvement is the HW4 software, which allows a 2-point temperature setting in the negative temperature range. This can be used for any HC2(A) sensor and/or HC2-PT100-B4 interface.

At the ELPRO Calibration Laboratory, which is accredited to SIST EN ISO/IEC 17025:2017, we also calibrate your measuring instruments to the best of our ability.

Author Katarina Žunko, source ROTRONIC: ”Hygropalm HP-GTS-Measuring device for paper industry”

January 2021

WRITE TO US or CALL US. Our experts will offer you the best solution for your wishes, requirements, application or field of use!

To je kratek članek, ki govori o točnosti naših EBRO termometrov

ELPRO Lepenik & Co. je ponosni partner nemškega podjetja EBRO, ki je specialist na področju termometrov in dataloggerjev, ki jih nudi najrazličnejšim panogam.

Po večletni uporabo EBRO termometrov, ti še vedno presenečajo s svojo neverjetno točnostjo in kakovostjo.

Po besedah našega vodje laboratorija, ko je komentiral odobritve certifikatov: “Take certifikate pa je res luštno podpisovati, ko termometri po letih uporabe skoraj nič ne odstopajo!”

Zdi se nam pomembno komunicirati tudi take izjave, ker prihajajo od ljudi iz stroke, od ljudi, ki vedo kaj delajo in kaj je na trgu na razpolago.

Da, lepo je če termometer opravlja svoje delo“.

Avtorica: Aleksandra Lepenik

oktober 2020

Dober zrak v zaprtih prostorih vpliva na učne in delovne procese.

Študija Švicarskega urada za javno zdravje poroča, da je kakovost zraka v več kot dveh tretjinah preiskovanih šol slaba.

Dober zrak je pomemben za optimalno učno okolje in ima velik vpliv na učinkovitost učencev in učiteljev. Slabo prezračeni prostori lahko negativno vplivajo na zdravje. Simptomi, kot sta utrujenost ali glavobol, se pojavljajo pogosteje. Običajno ni dovolj, da za nekaj časa odpremo okno. S tem ne dosežemo trajnega izboljšanja kakovosti zraka. Učne ure oziroma delo v pisarnah se po navadi pričnejo zjutraj, v neprezračenih prostorih, kar ima slab vpliv na kakovost zraka čez dan. Iz tega vidika je pomemben ustrezen sistem za nadzor kvalitete zraka. V nadaljevanju vam predstavljamo rešitev za boljši zrak v učilnicah in pisarnah – prikazovalniki CO2.

V zaprtem prostoru ob običajnih pogojih potrebujemo približno 25 do 35 kubičnih metrov svežega zraka na osebo na uro. To zagotavlja, da vsebnost ogljikovega dioksida (CO2) ostane pod 1.000 ppm (ppm = število delcev na milijon [vrednost deleža ogljikovega dioksida v zraku]) ter, da se hlapne snovi, ki jih izloča človek, v zadostni meri izločijo. Ker so danes številne zgradbe neprodušne in osnovno prezračevanje več ni zagotovljeno, kakovost zraka v zaprtih prostorih trpi, kar povzroči na primer plesen. Neprepustna zgradba zato potrebuje učinkovit koncept prezračevanja. Enako velja za vso nameščeno opremo. Cilj je uporaba materialov, ki v največji možni meri ne izpuščajo škodljivih snovi.

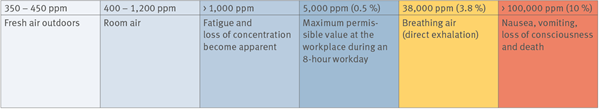

Smernice za CO2 v ”delcih na milijon” (ppm)

Tu nastopi naš partner Rotronic, s svojimi profesionalnimi merilnimi instrumenti. Podjetje je razvilo prikazovalnik za merjenje CO2 – CO2 dispay, ki preprosto in praktično meri kakovost zraka, temperaturo in vlažnost v prostoru. Kompakten instrument (stenski ali namizni) je enostaven za uporabo in prikazuje podatke na enostaven način; je dobra naložba. Prikazovalniki se postavijo v učilnice in so vidni tako učiteljem kot učencem. Na tak način je mogoče primerjati spremljanje kakovosti zraka z izobraževalnim učinkom. Otroci se ob tem naučijo, kako pomembno je prezračevanje za zdravje in dobro učno okolje. Z instrumenti je mogoče določiti, v katerih prostorih je kakovost zraka še posebej problematična.

Za analizo podatkov se lahko uporablja brezplačna programska oprema Rotronic SW21. Podatki iz te programske opreme se nalagajo na USB-pogon.

CP11 prenosni instrument za CO2, vlažnost in temperaturo meri in beleži CO2, vlago in temperaturo. Izračuna tudi rosišče in temperaturo mokre žarnice. Opremljen s terensko preizkušenim senzorjem vlažnosti ROTRONIC HYGROMER® IN-1, ta instrument ponuja neverjetno vrednost za denar. S pomočjo programske opreme ROTRONIC SW21, ki je priložena napravi, ga lahko nastavite po potrebi ter prenesete, shranite in analizirate podatke.

Namizna prikazovalna CL11 enota je merilnik, ki beleži CO2, relativno vlažnost in temperaturo. Primeren je za notranjo uporabo (učilnice, konferenčne sobe, pisarne, kinematografi …) in ponuja nepremagljivo kakovost po ugodni ceni.

Omenjeno problematiko kakovostno rešuje tudi naš partner Wöhler. Iz njihovega programa izpostavljamo merilnik CO2 – CDL 210 data logger. Merilnik deluje kot spominska enota za merjenje koncentracije CO2, temperature in vlage v notranjih prostorih (konferenčnih sobah, učilnicah pisarnah, ipd.). Z merjenjem omenjenih parametrov lahko analiziramo težave, kot so nelagodje, vlaga, plesen, težave s koncentracijo itd.

Morda vam bolj ustreza prikazovalnik CO2 – CDL 110 . Merilnik deluje kot prikazovalnik koncentracije CO2, temperature in vlage v notranjih prostorih (konferenčnih sobah, učilnicah pisarnah, ipd). Z merjenjem omenjenih parametrov lahko analiziramo težave, kot so nelagodje, vlaga, plesen, težave s koncentracijo itd.

Senzor ravni ogljikovega dioksida T5000 našega partnerja COMET vam bo ob prekoračitvi koncentracije CO2 zasvetil zeleno, rumeno ali rdeče.

U8415 s tremi barvami prikazuje koncentracijo CO2 v stavbah in notranjih prostorih. Opremljen je s senzorjem NDIR z dvojno valovno dolžino in večtočkovno kalibracijo, ki ne potrebuje vzdrževanja in je dolgoročno stabilen.

Prostorski prikazovalnik IQ 300 meri vsebnost CO2, vlažnosti in temperature rosišča. Prikazuje trenutne vrednosti, lahko pa napove tudi trend. Ko je prednastavljena vrednost presežena, enota jasno opozori s svetlobnim signalom in opozorilnim tonom.

Iz programa COMET na voljo tudi:

☏ Pokličite nas: +386 2 62 96 720

Za mnenja in razlage sta vedno na voljo:

strokovnjakinja za temperaturne meritve: Aleksandra Lepenik

strokovnjak za meritve: Zoran Lepenik

Avtorica: Katarina Žunko, vir: PST: ”Measurements for better air quality without CO2”

september 2020, revizija oktober 2023

ELPRO LEPENIK & CO. d.o.o. iz programa naših partnerjev predstavljamo (brezstične) termometre za merjenje telesne temperature.

Izpostavljamo:

poenostavljeno delovanje hitro, enostavno in natančno merjenje praktična žepna oblika za vsakodnevno uporabo območje merjenja temperature -50 °C … +250 °C skladen s HACCP in DIN EN 13485, vključno s certifikatom o kalibraciji osvetljen zaslon za branje v temi vodotesno ohišje (IP65) za uporabo na številnih področjih

točnost: ±2 °C + 0.05 °C na °C pod 0 °C (pri -60 … 0 °C) ±2 °C (pri 0 … 15 °C) ±1.5 °C (pri 15 … 35 °C) ±2 °C ali 2 %, velja večja vrednost (pri 35 … 550 °C) zaščitni razred: IP54 merilno območje: -60 … 550 °C

HACCP, gastronomiji, skladiščenju, živilski industriji, transportu, pri meritvah temperature površin, pri meritvah pogojev okolice …

POSEBNOST: ker se merilnikoma lahko izklopi laser, sta tako primerna za meritve človeške temperature (za namene ukrepov COVID-19).

NATANČNO MERJENJE TELESNE TEMPERATURE Z UMERJENIMI TERMOMETRI, ki vam jih v ELPRO Lepenik & Co. d.o.o. Laboratoriju za kalibracije (akreditiranem po SIST EN ISO/IEC 17025:2017), v skladu z zmogljivostmi tudi kalibriramo.

Za povpraševanje oziroma zanimanje nas pokličite na: +386 (0)2 62 96 720 ali nam pišite na info@elpro.si. Lahko nas tudi obiščete na naslovu v povezavi.

V družbi dnevno zaposlenim merimo telesno temperaturo z zgoraj omenjenim brezstičnim termometrom. Merilec meri temperaturo na čelu, na razdalji 3-4 cm. Ob tem upoštevamo kriterij:

☏ Pokličite nas: +386 2 62 96 720

Za mnenja in razlage je vedno na voljo:

strokovnjakinja za program EBRO: Barbara Čičak

Avtorica: Katarina Žunko, vir: EBRO A XYLEM BRAND

september 2020

ATEX certified sensors for use in potentially explosive areas “EX” are part of the programme offered by our partner COMET. The sensors provide accurate measurements of relative humidity, temperature and other units of humidity.

COMET System from the Czech Republic has been creating innovative control solutions by manufacturing dataloggers since 1991. These are used to document environmental conditions in production plants, warehouses and the cold chain. COMET instruments are characterised by high-quality measurement components, precision measurement and monitoring. The monitoring process consists of measuring, recording and managing data. Depending on the stability of the data, criteria for triggering alarms are set.

ATEX certified sensors for use in Ex zones – features:

The ATEX certified transducer range includes the following transducers: T3110Ex, T3111Ex, T3113Ex. All selected models are available from us!

Benefits

High-precision humidity sensors, modularity and multi-connectivity. The sensors come with a warranty. The measured values can be converted into other units of humidity using the function, such as: dew point temperature, absolute humidity, specific humidity, mixing ratio, specific enthalpy.

At the ELPRO Calibration Laboratory, which is accredited to SIST EN ISO/IEC 17025:2017, we can also calibrate your sensors.

For use in:

construction, infrastructure, heavy industry, meteorology, pharmaceuticals, laboratories, warehouses and wherever optimum humidity and temperature conditions need to be ensured.

ATEX-certified transducers are suitable for indoor and outdoor use, in potentially explosive areas.

Author.

June 2020

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]