senzorji: vlažnosti: Rotronic HT-1 / temperatura: PT100 1/3 DIN razreda B obseg uporabe: -50 °C … 100 °C / 0 % RV … 100 % RV točnost pri 23 °C: ±0.8 % RV / ±0.1 K

☏ Call us: +386 2 62 96 720

They are always available for opinions and explanations:

Aleksandra Lepenik, expert in temperature measurements

Measurement expert Zoran Lepenik

You are invited to read related articles:

By Blaž Tomaž Vertačnik, Aleksandra Lepenik; October 2023

In line with the legislative proposal (7.4.2023) of the European Parliament and its right to repair, ELPRO LEPENIK informs that we have been integrating this sustainability aspect into our production and sales programme from the very beginning - all our products are repairable.

On 7. 4. 2023 to adopt the requirements of the legislative proposal on the right to repair. They advocated appropriate design of long-lasting products, labelling to better inform consumers and the extension of warranty rights.

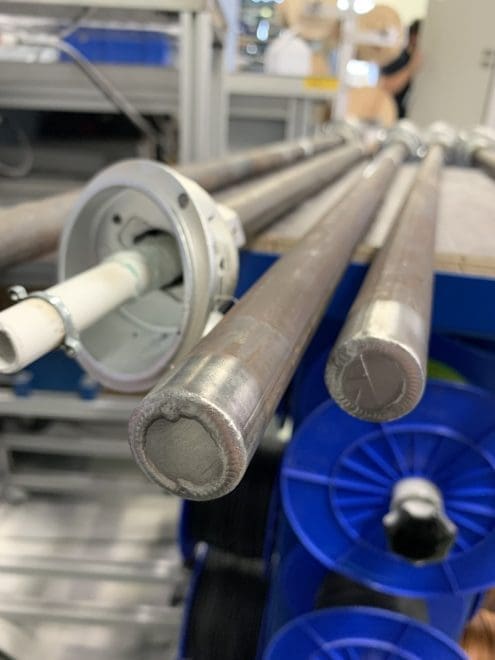

ELPRO LEPENIK temperature sensors are our product range of high quality and reliable temperature measurement products with integrated RTD and TC temperature sensors. Only these show the temperature change as a resistance or thermovoltage. They are connected to meters, i.e. to displays/control/automation/monitoring, which show the measured value as temperature. Standardised temperature sensors are designed to measure temperature in industrial processes.

The technical speciality of ELPRO temperature sensors is their design and concept, to which we pay great attention from the moment of agreement with the customer. This results in stable measurements for as long as possible, easier replacement (e.g. of the sensor and other components) and minimal downtime for the user. This is our main competitive advantage.

From ON SITE measurement and monitoring (on-site calibration), to quick exchanges of measuring inserts or sensor parts, to efficient and economical repairs of special designs and complex structures. We use systems and materials in our construction and design that increase the life and protection of our products. For trouble-free operation, with minimum maintenance and repairs. These steps ensure that our products are repairable, preserving the bulk of the expensive parts, which are often specially made (turned, milled) for the user. This conserves materials, labour, time, development, energy, right down to the raw material. What we can no longer use, we recycle. As members of the CIRCI project, we are looking for ways to reuse parts that would otherwise end up in recycling.

In addition to the advantages already mentioned, we also offer flexible design (made-to-measure). This has a positive impact on the energy efficiency or the efficiency of the tempering process. Our range of temperature sensors covers temperatures from -200 to +1800 °C, providing tailored solutions for a very wide range of users.

As the leading manufacturer of temperature sensors in Slovenia and self-proclaimed biggest fans of temperature measurement, we want to influence the positive effects of measurement, control and calibration. We don’t care where worn or faulty sensors end up (even if they are not made by us). We want to refurbish, repair, recycle or reuse the materials they contain. Today, sensors are the driving force behind digitisation. The sensor is where it all starts, and the number of measurements has increased dramatically. As a result, the demand and need for temperature sensors has increased significantly. And because they are not eternal – and have their own expected lifetime of stability and efficiency – suddenly there is a much bigger “rubbish heap” than we might be used to.

All our sensors are repairable, so we make it easy for customers to repair their sensor if it fails. The most commonly repaired sensors are the TTU-GLA, HIGH TEMP and PORTABLE sensors, as they are the most frequently used and subjected to the highest loads. However, we are also available for repairs of other sensors and will do our best to get your sensor back in service as soon as possible so that you can resume smooth production.

ELPRO LEPENIK temperature sensors are sustainably designed with the aim of reducing negative environmental impacts. We are deeply aware of the importance of sustainable development and we strive to implement all aspects of it in our processes. This results in waste reduction, recycling, reuse, remanufacturing and repair – and other aspects that help us extend the life of our products. The company has also adopted commitment to sustainability and is committed to sustainable development, energy efficiency and social responsibility. We declare that we will do everything in our power to work towards reparability, reuse, secondary use and recycling.

Aleksandra and Zoran Lepenik with ELPRO Lepenik and team

20.04.2023

☏ Call us: +386 2 62 96 720

They are always available for opinions and explanations:

Aleksandra Lepenik, expert in temperature measurements

Measurement expert Zoran Lepenik

Related articles:

Energy efficiency starts with the temperature sensor

Author Aleksandra Lepenik

April 2023

Process monitoring, routine controls and validations with EBRO loggers

EBRO (part of the Xylem Group) is a specialist in the manufacture of thermometers and data loggers for the pharmaceutical, medical, food and beverage industries, with a focus on reliable, precise and user-friendly instruments. From our partner EBRO’ s programme, we are proud to highlight EBRO data logger set for efficient process monitoring, routine controls and validations. We also highlight the quality of EBRO loggers based on their data storage as well as their alerting.

repeatable proof that the process consistently produces the required results.

a regular test to identify and determine the performance of the equipment.

ensures continuous verification of the execution of a specific procedure.

See also the following brochures for more information:

We also offer Ex loggers in our range that are ATEX classified. This means that the temperature gauges are suitable for use in hazardous areas/Ex zones (especially heavy industry, etc.).

The outstanding reliability of EBRO products (especially loggers) can be ELPRO Adhesive can confirm from our own experience. Based on this, in the figure below we show you an example where the battery capacity is already below 0% (i.e. it is already heading towards a negative state), which is displayed on the interface (where the logger is connected), as in the warning below:

EBRO loggers meet the requirements of 1G or EPL Ga. This requires the device to be designed with a very high level of safety (even in the event of rare disturbances). Loggers can be used in Zone 0.

ELPRO Adhesive In cooperation with EBRO, we are experts in measurement systems, scalable measurements and documentation systems (IQ-OQ protocols, etc.) for routine control and validation of various thermal processes.

At ELPRO Calibration Laboratory, we also calibrate your measuring equipment in accordance with SIST EN ISO/IEC 17025:2017.

You can find out more about these data loggers, their features, certification and operation in the following app .

Author Barbara Čičak

February 2021

ROTRONIC relative humidity and temperature meter - for the paper industry

From our partner ROTRONIC we present HP-GTS – the solution for the paper and printing industry, for the precise measurement of humidity and temperature, and the related equilibrium relative humidity in the paper and printing industry.

Discussions on environmental impacts during paper storage, transport, printing and finishing have existed since the beginning of industrial paper production. Generations of professionals have had to cope with major negative impacts in order to monitor and control temperature and humidity. Despite years of testing, some relationships are still not sufficiently clarified, if at all. There is still a lot of controversy in the practice of paper converting, in particular about the relationship between the atmosphere, paper and printing. In modern production facilities, paper intended for offset printing is prepared at a relative humidity of 50 % ± 5 % and at 40 % ± 5 % for digital printing. These humidity characteristics must be continuously monitored at all stages of the production process.

To keep the paper in optimal condition for the printing process, it is wrapped in a special packaging material that protects it from environmental influences and changes. The paper manufacturer has minimal influence on how the paper bundles or fibre gaps will react to the environmental conditions in the premises of the printers, bookbinders or end-customers.

Under normal printing conditions, there are problems related to direct atmospheric conditions. When printing problems occur, such as duplication of dots, incorrect entries, overlapping, curling, edge bleed, wrong dimensions, these atmospheric effects become significant. This is more likely to happen in seasons with extreme weather conditions – hot summers and cold winters. The latter causes poor print quality, especially in the levelling process. This has a negative impact on production processes, such as incorrect entries or interruptions due to breaks.

The value describing the evolution of relative humidity as a function of temperature depends on the accuracy of the measurements made. Here, the temperature measurement must be very precise. This means using thermometers that read in tenths of degrees.

Although accurate temperature measurements are relatively simple, the same cannot be said for reliable measurements of absolute or relative humidity. The practical problem with all humidity measurements is that they are made on relatively small amounts of moisture.

At a temperature of about 20 °C, an increase in moisture content of about 2 g/m³ causes an increase in relative humidity of about 10%.

As a hygroscopic material, paper strives to achieve equilibrium with the humidity of its surroundings. For this reason, the humidity of the air inside the paper structure must be equal to the humidity of the paper bundle. This value indicates the degree of equilibrium between the relative humidity of the paper and the ambient air. The equilibrium relative humidity ( ERH ) can be defined as the value of the relative humidity of the atmosphere at a given temperature at which the paper will neither gain nor lose moisture. If there is a difference between the relative humidity (% RH) of the atmosphere where the paper is located and the ERH of the paper, water vapour exchange can occur. This results in a change in the ERH and moisture content of the paper, which affects the quality of the paper. If the % RV and ERH are equal, no exchange will occur and all parameters will remain stable. In this respect, ERH is a very important factor in ensuring paper capacity and quality.

To determine the relative humidity of the air or the equilibrium relative humidity of the paper, it is necessary to measure the change in a measurable humidity-dependent parameter. Such parameters affected by moisture fluctuations include, for example, changes in the length of paper fibres, the conductivity of electrolytes and changes in the resistivity of semiconductors. In the practice of paper production and converting, these methods are widely used in measurement and control systems. The methods used to calibrate humidity instruments are very accurate and are based on the principle of measuring the dew point and determining psychrometric differences.

By measuring the relative humidity and the atmospheric temperature, it is possible to determine whether the quality of the paper will change after unpacking, thereby adversely affecting the planned printing. A difference between ERH and external humidity of up to ± 5 % RH is acceptable. When the humidity difference is too large (> 8-10% RH), water vapour is exchanged too quickly, resulting in deformation of the paper edges. The latter leads to poorer print quality and affects the amount of paper wasted.

Paper moisture content of more than 60% ERH can extend the drying time of the ink up to three times longer than usual. The optimum atmospheric humidity for the storage and transport of paper or cardboard is approximately 45 % RH (for temperatures between 10 °C and 30 °C). By observing the above storage conditions, ink drying can be optimised when the paper bundle is collected (to avoid major temperature changes in humidity). The length of time bundles of paper or cardboard can be stored depends on the temperature difference between the bundle and the ambient conditions, and the size of the bundle. As a general rule, the storage time is between one and two days, with a difference of 10 °C and a volume of 1m3. If the paper humidity is too low (<42% RH), it can lead to static, which affects the performance of the printing machine. This takes multiple sheets at once, leading to maintenance costs and delays.

Unwanted paper changes and printing delays can be avoided by measuring the ERH of the bundles and the temperature, using a relative humidity and temperature meter. From the Rotronic range, we offer the Hygropalm HP-GTS kit with portable instruments for measuring equilibrium relative humidity and temperature (paper bundles) with state-of-the-art technology.

HP-GTS replaces the long-standing GTS and GTS-set products.

Next to the meter Hygropalm HP-GTS we offer a number of sensors of different models and other instruments:

– Sword-shaped sensors for measurements in paper bundles

– sensors for measuring relative humidity and temperature with high accuracy

– sensors for measuring humidity, temperature and dew point

– mini relative humidity and temperature sensors

– calibration devices for relative humidity sensors

KEY FUNCTIONS:

Benefits:

Areas of use, applications:

measuring humidity in bundles of paper, cardboard and textiles for paper and textile machinery and printers.

A major improvement is the HW4 software, which allows a 2-point temperature setting in the negative temperature range. This can be used for any HC2(A) sensor and/or HC2-PT100-B4 interface.

At the ELPRO Calibration Laboratory, which is accredited to SIST EN ISO/IEC 17025:2017, we also calibrate your measuring instruments to the best of our ability.

Author Katarina Žunko, source ROTRONIC: ”Hygropalm HP-GTS-Measuring device for paper industry”

January 2021

WRITE TO US or CALL US. Our experts will offer you the best solution for your wishes, requirements, application or field of use!

To je kratek članek, ki govori o točnosti naših EBRO termometrov

ELPRO Lepenik & Co. je ponosni partner nemškega podjetja EBRO, ki je specialist na področju termometrov in dataloggerjev, ki jih nudi najrazličnejšim panogam.

Po večletni uporabo EBRO termometrov, ti še vedno presenečajo s svojo neverjetno točnostjo in kakovostjo.

Po besedah našega vodje laboratorija, ko je komentiral odobritve certifikatov: “Take certifikate pa je res luštno podpisovati, ko termometri po letih uporabe skoraj nič ne odstopajo!”

Zdi se nam pomembno komunicirati tudi take izjave, ker prihajajo od ljudi iz stroke, od ljudi, ki vedo kaj delajo in kaj je na trgu na razpolago.

Da, lepo je če termometer opravlja svoje delo“.

Avtorica: Aleksandra Lepenik

oktober 2020

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]