Solutions for efficient level measurements of (sticky) bulk/loose materials

ELPRO Adhesive from our partner MOLLET, we highlight instruments and related solutions for measuring the density and/or level of bulk materials.

In our programme you can find:

– level switches,

– pipe diaphragm valves,

– continuous level gauges,

– intelligent hose connectors.

The density of the bulk solids varies widely but is very important for the selection of the appropriate level measurement device.

V thetable of bulk/spillable substances/materials lists (alphabetically) all the bulk/spillable substances or bulk materials that can be measured with the MOLLET instruments of our product range.

Level monitoring in sticky or dry bulk/dispersible materials is a difficult task that most measuring devices are not up to. Bulk materials often occur as intermediate products of the production process in batch mixers and homogenisers. In the manufacture of various products, liquids such as molasses, fats or oils are added to the dry bulk material. After the liquid is dosed, the adhesion forces of the mixture increase dramatically, leaving the level measurement devices to deal with solidification and contamination. This results in unreliable measurement results.

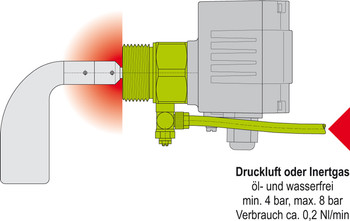

MOLLET has developed a solution for these demanding applications. The already robust and insensitive rotary paddle switches of the MOLOSroto series have the additional option of pressure encapsulated annular slots as a flushing option. A small amount of compressed air or inert gas continuously flows through the annular gap of the seal and flushes it out. This prevents the lip of the sealing ring from sticking together and cleans the gap. The pressurised housing also protects the shaft bearing from moisture ingress from wet, oily and sticky product. This ensures reliable level monitoring for complex products.

Level indicators are used to monitor and measure levels. They are often called rotary level switches , rotary vane switches, rotary vane level indicators, rotary vane limit switches, rotary vane LevelCheck, level indicators, level sensors or level switches.

Features:

Author Katarina Žunko

November 2020

experts will offer you the best solution according to your wishes, requirements,

the scope or application!

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]