PyroMiniBus miniature infrared (IR) temperature sensor CALEX

Po naročilu. Pošljite povpraševanje.

Dobavni rok: 3 weeks

- IP65 (NEMA 4)

- accuracy: ±1 % of reading or ±1 °C, whichever is greater

- repeatability: ±0,5 % of the reading or ±0,5 °C, whichever is the greater

- t90 response time: 125 ms

- spectral range: 8-14 µm

- supply voltage: 24 V DC (min. 6 V DC/max. 28 V DC)

- dimensions: 18 x 45 mm

- cable length: 1 m

- weight: 85 g

- EN61326-1, EN61326-2-3, RoHS standards

- operating temperature range: -20 … +1000 °C

Description

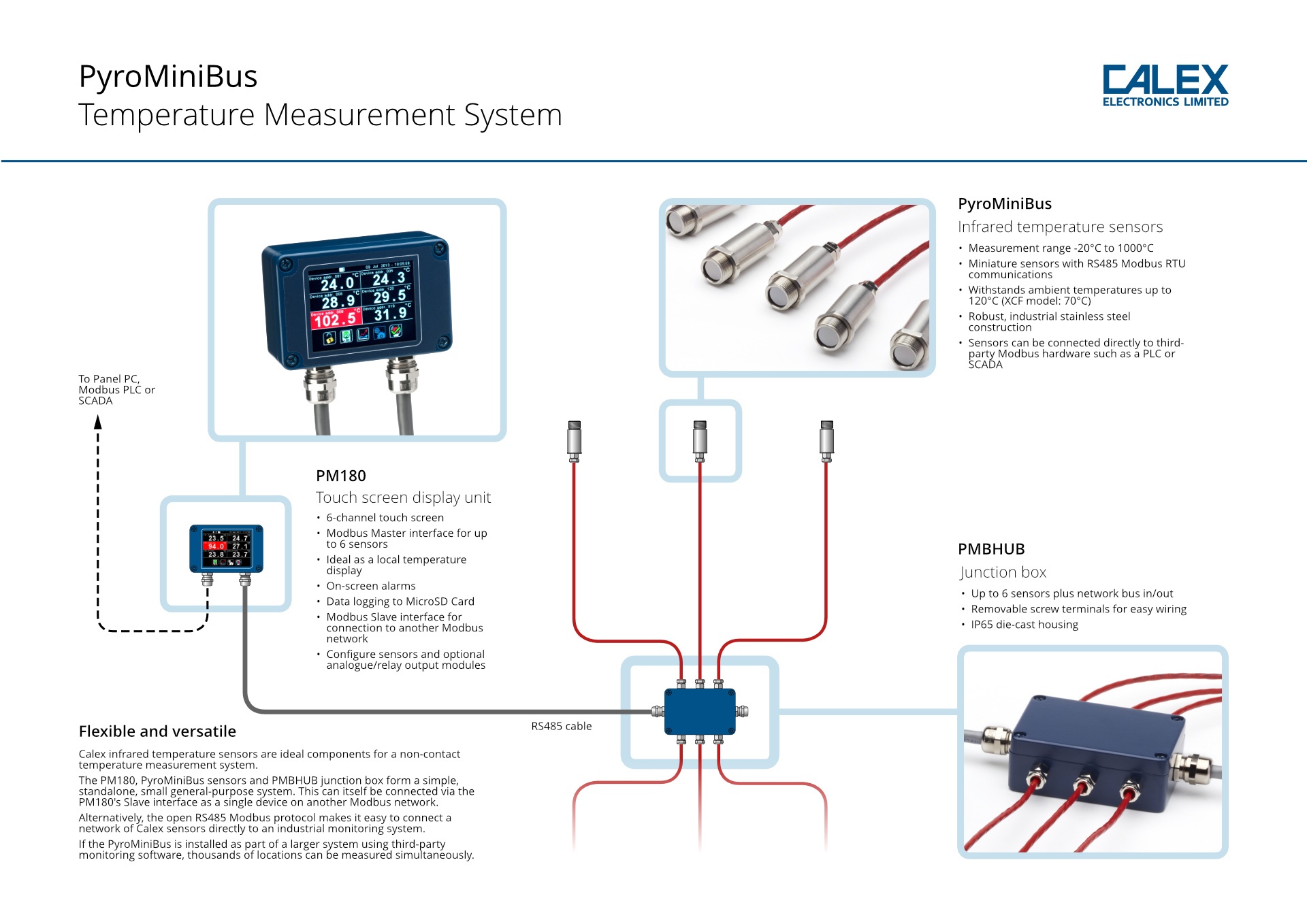

The CALEX PyroMiniBus miniature infrared (IR) temperature sensor is suitable for measuring temperatures in the measuring range -20 °C to 1000 °C, with ambient temperatures up to 120 °C. The sensors have RS485 Modbus communication, allowing them to connect directly to Modbus hardware.

They are IP65 rated, made of 316 stainless steel and fully tested to industry EMC standards. They can be used to measure the temperature of food, paper, plastics, asphalt, paint, loose and organic materials, as well as the dirtiest, rusty or greasy surfaces. The sensors measure just 45 mm, so they can fit into even the smallest space.

Benefits

- RS485 Modbus for multi-channel installations (connect up to 247 sensors)

- measuring range: -20 … +1000 °C

- ambient temperature: 0 … 120 °C

- Ideal for continuous temperature monitoring in multiple locations

- adjustable emission: 0.20 to 1.00

- IP 65 protection

PyroMiniBus features

- compatible with RS485 Modbus Master devices or PM180 touch screen (optional)

- not intended for measuring body temperature

- accuracy: ±1 % of reading or ±1 °C, whichever is greater

- repeatability: ±0.5 % of reading or ±0.5 °C, whichever is greater

- t90 response time: 125 ms (90% response)

- spectral range: 8-14 µm

- supply voltage: 24 V DC (min. 6 V DC/max. 28 V DC)

- supply current: maximum 50 mA

- material: stainless steel

- dimensions: 18 x 45 mm

- cable length: 1 m

- weight: 85 g

- Standards: EN61326-1, EN61326-2-3, RoHS

6-channel PM180 touchscreen terminal (optional)

- configuration, display, data logging and alarms

- Connect up to 6 sensors

- acts as Modbus Master and Slave

- recording large amounts of data on a MicroSD card

- bright touchscreen with backlight

- analogue and relay outputs via optional ICPDAS Module M-7061 and M-7024

- two-channel temperature graph

- Languages: english, chinese, japanese

Examples of use

Drying ovens

The epoxy-impregnated glass fibres are cured in the oven to increase their strength. PyroMiniBus sensors are installed in the oven at temperatures up to 120 °C to create a temperature profile at multiple points across the entire surface to be treated and report the measured temperature to the heating system, which controls the oven’s hot air blowers. The industry includes boat building and aerospace.

Industrial bakery

Check the temperature profile of the bakery products at several points along the conveyor oven.

Corrugated board production

Monitor temperature along the entire carton, with local displays for each part of the production line and centralised control in the control room. The sensors can withstand 120 °C and can be used in high-temperature areas such as single panels without the need for cooling.

Automobilism

A large PyroMiniBus sensor system can monitor the paint curing process at multiple points. Monitor temperatures around the whole vehicle in the test chambers.

Monitoring the situation

The sensor network can monitor all bearing temperatures on the machine, on the spill table or in the whole factory. PyroMiniBus is ideal for measuring the temperature of all painted metal surfaces.

Infrared curing

A set of sensors mounted on the infrared lamp plate ensures a uniform temperature profile along the hardened part. Surface coatings, paints and epoxies, among others, are ideal target materials.

Filling a gas cylinder

Control temperatures to improve the repeatability of the filled volume and improve filling efficiency. It is easy to monitor the temperature of each cylinder on the filling machine without having to manually move the contact probes.

For installation instructions, accessories and to order, please follow this link.

You can find much more useful information in the Documentation tab. Please refer to the technical documentation for options, add-ons and accessories.

Povpraševanje

You may also like…

For your victories, with our solutions. Call us:

Contact us.

Call us:

+386 (0)2 62 96 720

Email us:

[email protected]